What Is Intercept Technology™

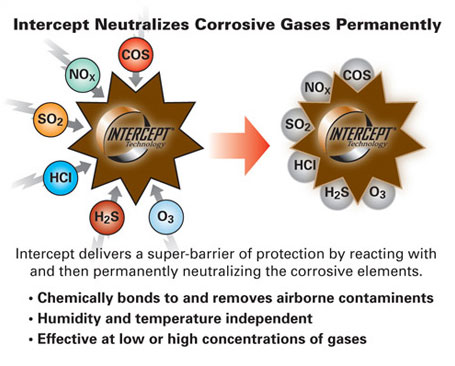

Intercept Technology™ is an oil-free, volatile-free, complete anti-corrosion packaging system. Intercept Technology™ is on the forefront of corrosion prevention in a wide variety of industries such as oil and gas, automotive, medical, and other countless applications. Intercept Technology™ uses a proven copper-based technology which is permanently reacted and suspended into a plastic matrix (polyethylene) which when exposed to air, reacts with all corrosive gases and elements, preventing those gases from affecting any materials stored inside its barrier. The protection that Intercept Technology™ provides begins at the microscopic level – airborne gases such as hydrogen sulfide, sulfur dioxide, ozone, chlorine, nitrous oxide, and many others – attack the uniquely formulated copper of the bag before the materials stored inside, thus keeping your equipment safe.

Intercept Technology™ was designed to protect all materials under all environmental conditions equally. Intercept’s effective operating temperature range extends from -42°F to 170°F, does not degrade under normal storage, shipment, or use conditions, and can be opened, closed, and reopened as needed. Intercept™ is proven effective with any degradable material – metals, plastics, rubber, paint, fabric, paper, leather, ceramics, and digital/magnetic surfaces.

How Intercept™ Works

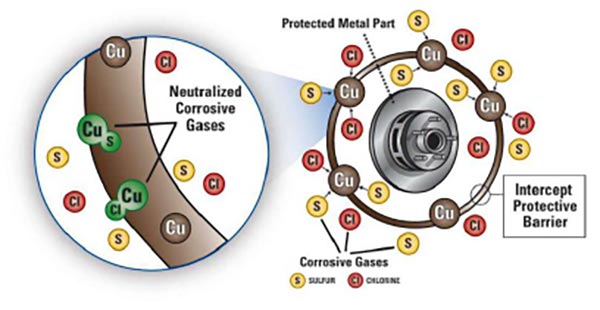

Intercept™ works differently than traditional anti-corrosion packaging. It is not a VCI (volatile corrosion inhibitor) that coats the product with a chemical film, creating a barrier. Intercept delivers protection by reacting with and then permanently neutralizing aggressive corrosive elements in the air.

Only Intercept™ utilizes high-surface area Copper particles (Cu) that are bound into the polymer-matrix. Their unique ability to quickly and efficiently neutralize corrosive gases provides protection against corrosion — without vapors or volatiles — like no other material available for industry.

Intercept is 100% non-hazardous, works indoors or outdoors and stops corrosion without sprays, coatings, or volatile chemicals.

Call (281) 784-2262 to learn more.

What is Corrosion?

Your Equipment is Under Attack – Materials & What Damages Them

- Nitrous Oxides (NOx) – forklift exhaust, automobile exhaust, unvented heaters. Includes amines, amides, ammonia, nitrates, nitrites.

- Ozone (O3) – highly reactive oxygen (smog, etc.) Accelerates the degradation of materials in conjunction with other reactive gases. Affects rubber, plastics, paper, fabrics.

- Hydrogen Sulfide (H2S) & Sulfur Dioxide (SO2) – Exhaust from cars, effluent from paper mills, oil refineries, heavy industry, decaying vegetation, outgasing from corrugated cardboard, adhesives, etc.

- Carbonyl Sulfide (COS) – Very aggressive form of sulfur; Result of fossil fuel combustion, wood fires; prominent on oceans, can linger up to 50 miles from ocean source.

- Hydrogen Chloride (HCl) – Very aggressive; prominent on oceans; residue of coal burning; hydrochloric acid may form in moist air.

Learn how INTERCEPT TECHNOLOGY

protects against corrosion.

Call (281) 784-2262 to learn more. Or request a quote.